Custom Rubber Molding

Our commitment to excellence is exemplified through our proficiency in custom rubber molding processes and our unparalleled expertise in formulating optimal rubber compounds, positioning us as the ideal supplier for your unique molded components.

Home

Our Custom Rubber Molding Services

At Robinson Rubber Products, we take pride in offering a comprehensive range of custom rubber molding services that cater to your diverse needs, spanning from prototype part development to high-volume molding capabilities. Our commitment to quality is unwavering, ensuring that your custom molded products meet the highest standards of precision and performance.

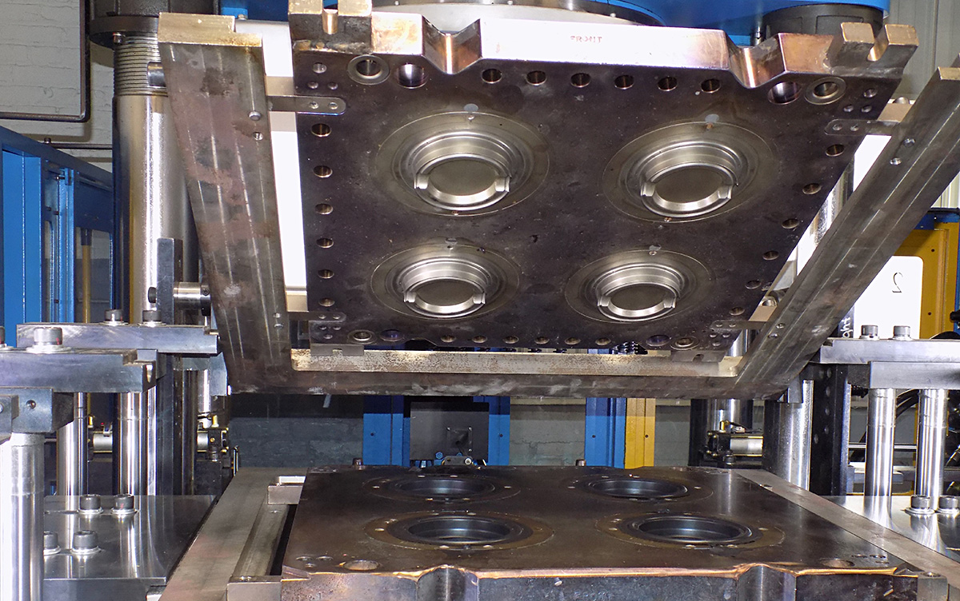

Compression Molding

Compression molding is a type of molding that uses both pressure and heat. The raw material is inserted into the heated mold chamber for compression molding. Plugs are then placed into the mold cavity’s top. Not only are the plugs used to seal the mold chamber. They are intended to pressurize it instead. The raw material starts to cure inside the mold cavity as a result of exposure to heat and pressure, creating a new product or component.

Injection Molding

Rubber injection molding is when uncured rubber is transformed into a usable product by injecting raw rubber material into a mold cavity made of metal. The applied pressure produces a chemical reaction like vulcanization or curing, which causes the cross-linking of the polymer chains inside the material.

Transfer Molding

One of the many processes used by engineers to create rubber items is transfer molding. The correct quantity of molding material is measured, inserted, and put into the molding pot before the process begins. Pressure forces the material to transfer into the mold cavities as it is heated.

Custom Formulation for Optimal Performance

Robinson Rubber Products takes pride in our vast repertoire of over 2,000 compound formulations, meticulously developed to address a wide spectrum of specialized needs. Our team of seasoned chemists and engineers possesses the expertise to create rubber solutions that optimize the performance of your components in diverse applications.

Which application is best?

Each application carries its own set of advantages and applications. Our experienced engineers and chemists are here to help ensure that we choose the right process and formulation and process for your project. Whether your are trying to meet tight specifications, choose the proper application for your project, or minimize labor costs, we have a solution for you! Our Designing with Rubber guide serves as an excellent tool to get you started in the right direction.

Compression Molding

- Simple designs

- Economical tooling costs

- High stability products

- Corrosion resistant products

Injection Molding

- High efficiency = reduced labor costs

- Great for uniform, intricate designs

- Minimal to no flash produced

- High volume production

Transfer Molding

- Fastest process

- Low waste, near-flashless parts

- Complex parts with tight tolerances

- Greater uniformity

At Robinson Rubber we recognize that each and every part requires a tailored approach to ensure that your project goals are met. Our engineers will collaborate with you to ensure an optimal design is created, a precise formulation is selected, and the right process is choses to meet your needs.

Our Comprehensive Approach

In-House Compound Formulation

Our dedicated team works to formulate compounds tailored to your unique requirements, ensuring optimal performance and durability.

Full Mixing Capabilities

Benefit from our advanced mixing capabilities that guarantee uniformity and consistency in every molded product we deliver.

Extensive Polymer Families

Choose from over 20 polymer families, allowing you to select the perfect material for your specific application. View our Polymer & Material Selection Guide

Variety of Compound Characteristics

Tailor your components with a diverse range of compound characteristics, ensuring the perfect fit for your project.

ELEVATE YOUR PROJECTS WITH CUSTOM RUBBER MOLDING

Count on Robinson Rubber Products to not only meet but exceed your expectations. Our team is ready to assist you with designing specifications, providing technical expertise, and ensuring that your custom molded products are a testament to precision and quality. For technical assistance with your custom molded products, click here to connect with our experts and embark on a journey of innovation and excellence.

Elevate your projects with Robinson Rubber Products – where precision meets perfection in custom molding.